G.200

Automation in your production line

To enable fully automated operation of the compactor, the container can be equipped with a level sensor. When the container reaches its maximum capacity, the upstream system (such as a conveyor belt) will automatically stop or start. This continuous material flow prevents overfilling of the container.

Increased flexibility in product discharge due to greater pipe height

The pipe length can be extended up to 5 metres without the need for a conveyor belt to discharge materials into containers or receiving tanks. The increased height of the WEIMA compactor allows it to be installed in an optimal position tailored to the specific requirements of your space.

Containers are available in various sizes to suit different applications

You can choose from a variety of container sizes to meet your needs: 220 litres, 600 litres, 800 litres, 1,200 litres, or 2,000 litres. Additionally, containers can be equipped with either manual or automatic lids to ensure safety and maintain hygiene.

The G.200 machine compresses cans into 200 mm discs

Impeccable hygiene with a cleanable design

Safe and clean with a cleanable design – WEIMA dewatering compactors ensure food safety, comply with hygiene standards, and simplify the cleaning process, minimising downtime

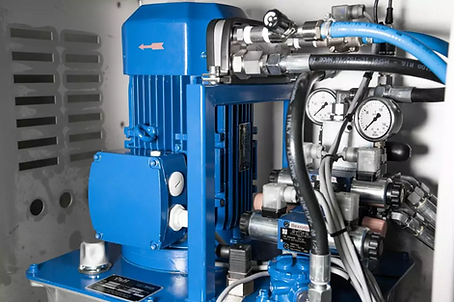

Multi-shift operation is made possible with hydraulic oil cooling.

Automated multi-shift operation is seamless with hydraulic oil cooling via a heat exchanger. This system maintains a stable operating temperature for the hydraulic oil, preventing overheating.

An easy-to-use touchscreen for quick parameter adjustments and diagnostics.

The Siemens control system with a touchscreen simplifies parameter settings, such as pressing force, timing, or repeat compression functions. Accurate diagnostic messages minimise downtime. Additionally, the entire system can be seamlessly integrated into a PROFINET network, enabling convenient control of upstream and downstream systems such as conveyor belts or lift-and-tilt stations.

Did you know?

To ensure the longevity of the G model, we use high-quality stainless steel, providing excellent protection against wear and corrosion for both the machine and the control cabinet while ensuring low maintenance and hygienic standards

Easy to clean and maintain with a pre-cleaning system and additional maintenance access points.

If needed, the G model can be equipped with a pre-cleaning system. Multiple nozzles installed inside the machine perform initial cleaning and remove coarse debris, making manual cleaning easier afterward. Five maintenance hatches provide convenient access to the machine for cleaning and maintenance tasks.

An automatic cleaning system is also available as an option. This system automatically cleans the dewatering compactor using internal nozzles that can deliver up to 20,000 litres per hour. The integrated software manages the entire cleaning process seamlessly.

Automatic liquid drainage with level detection in the drainage tray.

If needed, liquid drainage can be automated using level sensors in the drainage tray. These sensors control the discharge of compressed material and automatically shut down the recycling compactor when the downstream process halts. A screw pump is used for viscous liquids, while a radial pump is employed for standard liquids.

Clean discs with a post-cleaning system.

To remove any residue remaining on the discs (such as yogurt remnants), a post-cleaning system in the form of spray nozzles can be installed on the discharge pipe. Cooling water from the oil cooling system is utilised for this purpose.

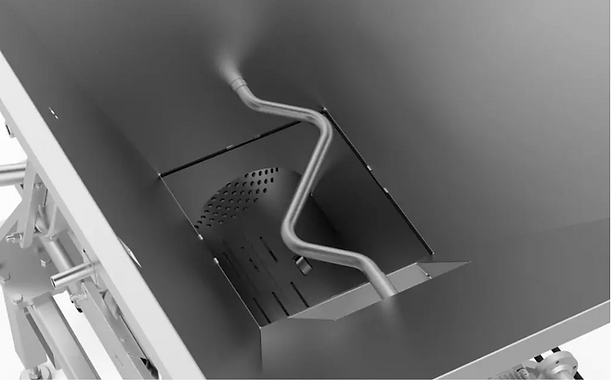

No material build-up thanks to the horizontal agitator.

A horizontal agitator can be installed in the container as an optional feature. Continuous material circulation prevents build-up inside the container and ensures consistent material feeding.

A variety of screen sizes to accommodate all types of packaging.

The walls of the compression chamber are perforated to allow drained liquids to flow out. The screen size can be customised to suit the properties of your materials. For sticky materials like yogurt or sour cream, screens with a maximum hole diameter of 12 mm are commonly used. For liquids, smaller screen holes as small as 4 mm can be applied. This ensures that small particles from the packaging do not enter the drainage tray along with the liquid.

Technical Information

Get to know our machinery in detail.

Product Diameter (mm)

Production Rate

Efficiency

Residual Moisture

G.200

200

Up to 4.2 cubic metres per hour

7.5kW l 400v l 50Hz

3-30%